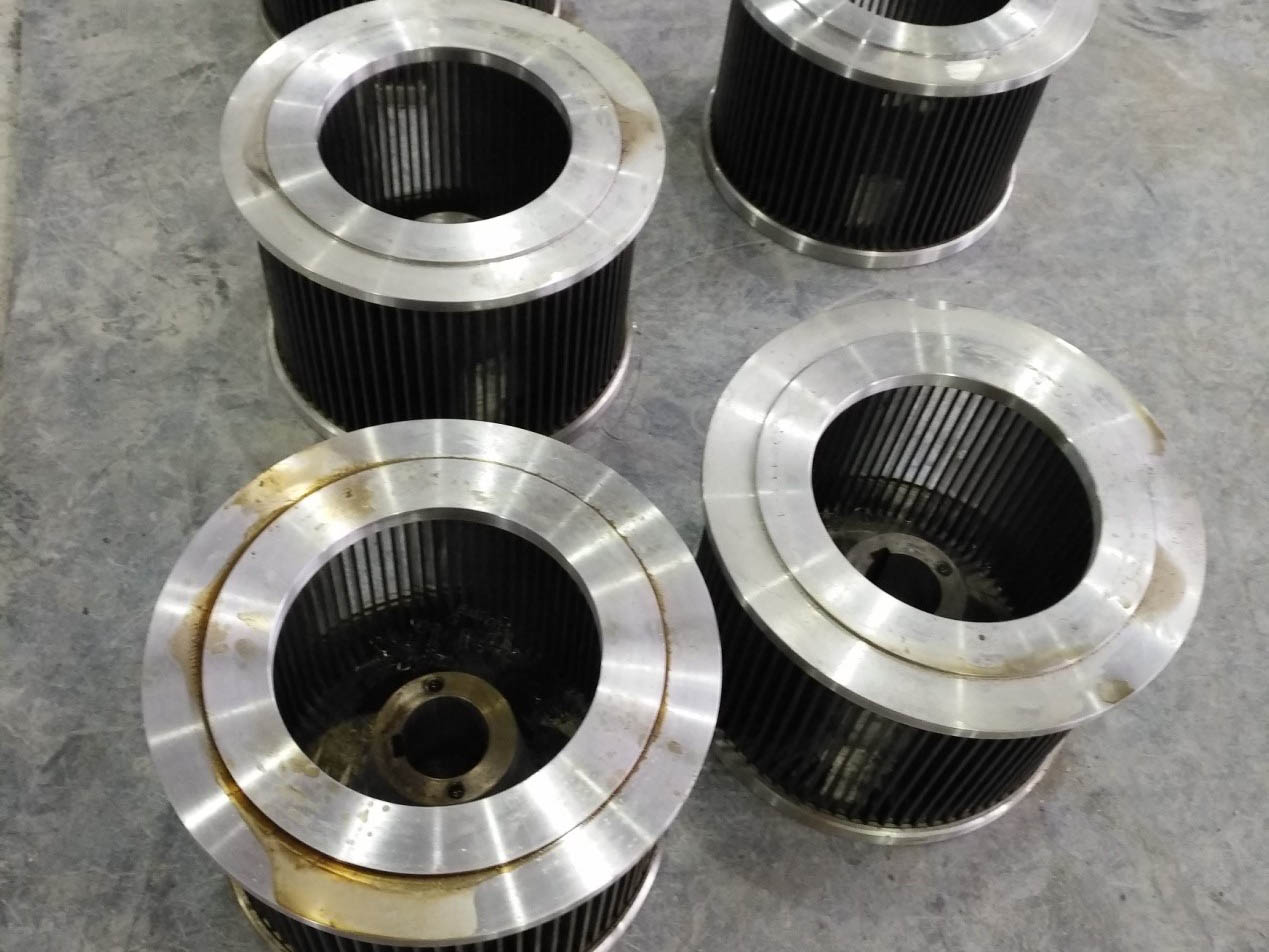

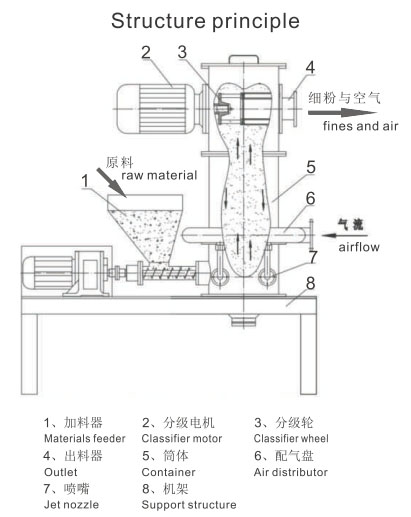

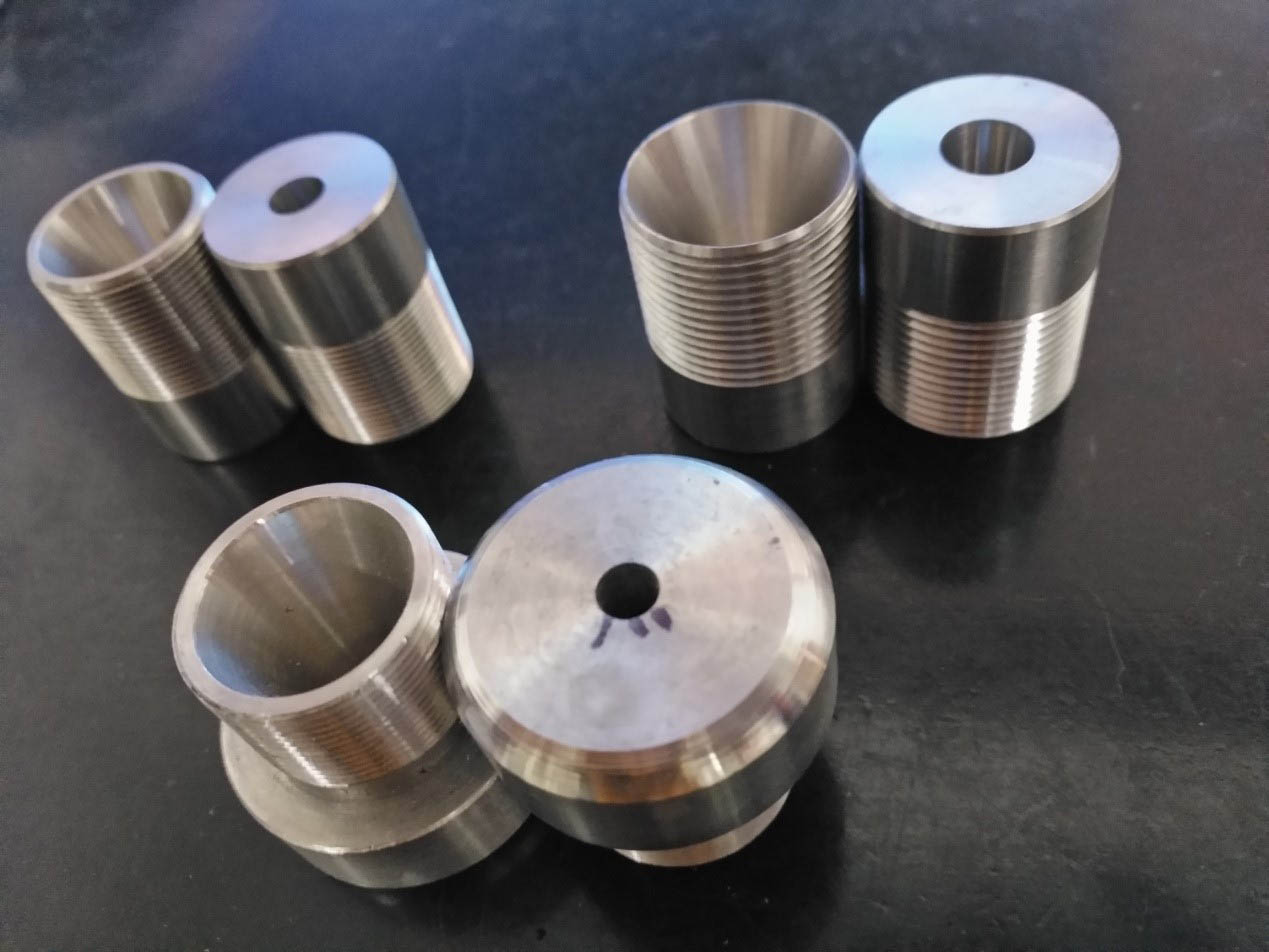

Likaroloana tsa Jet Mil

1.ho beha kantle, thibela thepa ho kena ka hare, ebe jeme.

2.valve le valve ea mantlha ke likarolo tsa ho lahla, ha ho na deformation ka mor'a tšebeliso ea nako e telele.

Ts'ebetso ea 3.CNC e tiisa ho nepahala hantle.

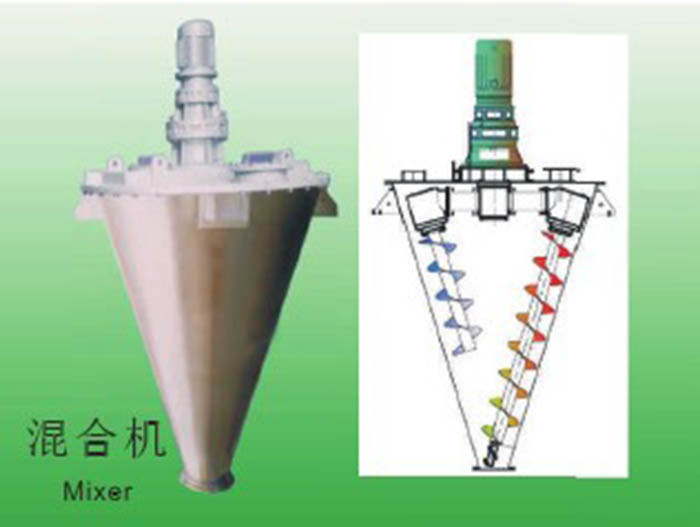

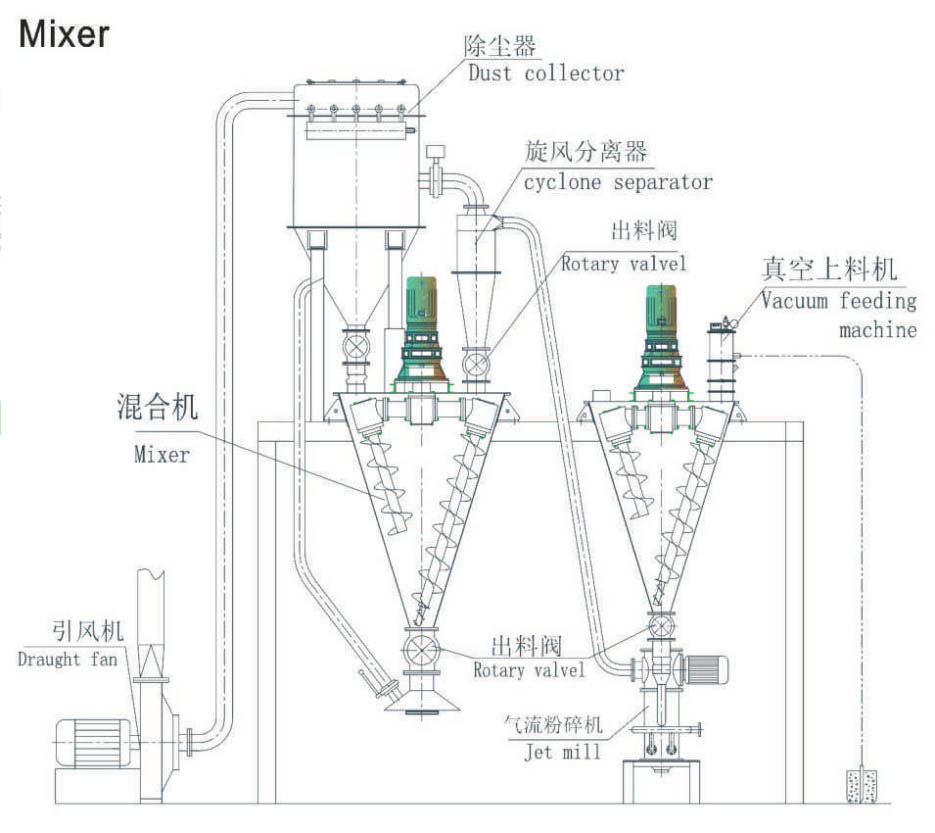

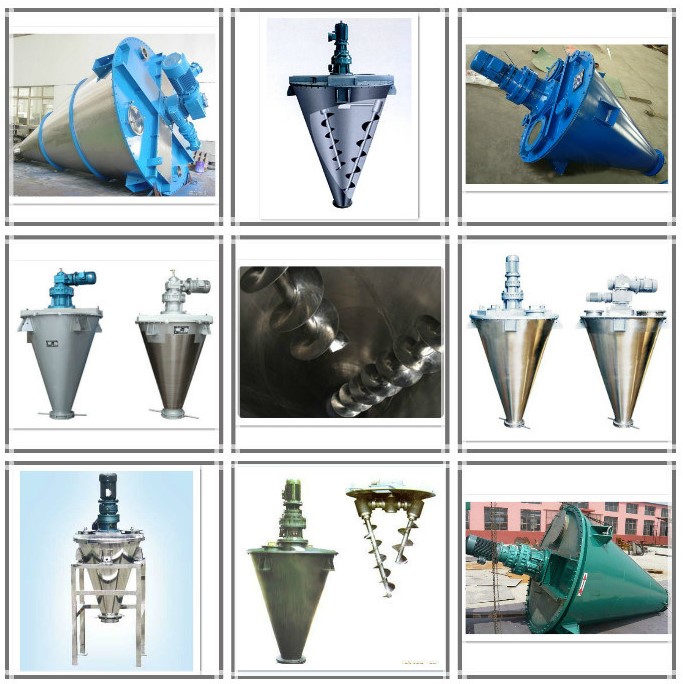

Tlhaloso

DSH double screw mixer e kopanya phofo, granule le motsoako oa metsi. Ho potoloha ha twin screw mixer ho phetheloa ka sete ea li-motor le li-reductions tsa cycloid. Ka ho kopanya asymmetric ka li-screws tse peli, sebaka se susumetsang se tla atolosoa 'me lebelo le tsosang le tla potlakisa. Mochine o kopanyang o khothalletsoa ke li-spiral tse peli tse sa tloaelehang tsa ho potoloha ka potlako, ho etsa litšiea tse peli tse sa tšoaneng tse phallang holimo ho tloha leboteng la cylinder. Ho reteleha letsoho le khannoang ke spiral orbit, ho etsa hore lintho tse spiral tsa boemo bo fapaneng ka har'a stud ka enfelopo, dislocation karolo ea lintho tse bonahalang e ntse e kgothaletswa, karolo e 'ngoe ea lintho tse bonahalang e ntse e lahleloa screw, e le hore ho fihlela lintho tse tletseng selikalikoe jereng kamehla ntjhafatswa. Lisebelisoa tse peli tse boletsoeng ka holimo li kopanngoa hape ho sekoti sa concave sa setsi, ho etsa phallo e theohelang ea thepa le ho tlatsa lesoba ka tlaase, kahoo ho etsa potoloho ea convective.

Sebopeho

1.Homogeneous ho kopanya

2. Nako e khutšoanyane ea ho kopanya 5-15 metsotso

3. Hloekisa ho tsoa 'me ha ho letho le setseng

4.Bohareng ba ho ntša valve:

Electronic, pneumatic, manual (boikhethelo)

Belofo ea bolo, belofo ea sekoti, belofo ea heke ea thipa, valve ea serurubele (ho ikhethela)

5.Main shaft tiiso: Stuffing tiiso le air purge tiiso

6.Drive: Siemens motor, cycloid kapa gear reducer

7.Moeli / polokeho switjha (boikhethelo)

8.Baki ea ho futhumatsa / e pholileng ka boikhethelo)

Sesebelisoa sa Cone mixer:

1.Applicable thepa karolo ea ba futsanehileng, likaroloana phofo ke thepa e batlang e le khōlō;

2.E loketse bakeng sa ceramic glaze ho kopanya mokhoa o bonolo, likaroloana tsa thepa ha li fepehe kapa li robehile;

3.Lisebelisuoa tse thibelang mocheso li ke ke tsa chesa haholo;

4.Ka phofshoana - mokhoa oa ho kopanya phofo o bonolo haholo ho eketsa maemo a ho sebetsa kapa ho fana ka mokelikeli ho plurality ea spray outlet bolela;

5.Belofo e ka tlase ea lisebelisoa tse bonolo tsa dislocation, kaha botlaaseng ba spiral ha ho na lisebelisoa, kahoo ha ho na khatello e feptjoang ketsahalo.

Molao-motheo oa ts'ebetso:

Motsoako o otlolohileng oa lithane tse peli o na le tanka e tšekaletseng e bopehileng joaloka U, sekoaelo se kaholimo se nang le menyetla (kapa ntle le), shaft e le 'ngoe e nang le likarolo tse peli tse kopanyang ribone, yuniti ea phetisetso, foreimi ea tšehetso, ntho e tiisang, sebopeho sa ho lahla joalo-joalo. Li-Ribbon blades li lula li le mekhahlelo e 'meli. Ribone e ka ntle e etsa hore thepa e kopane ho tloha lintlheng tse peli ho ea bohareng, 'me lente le ka hare le etsa hore lisebelisoa li hasane ho tloha bohareng ho ea ho tse peli. Lisebelisoa li etsa vortex nakong ea ho sisinyeha khafetsa le ho kopanya homogeneous ho finyelloa.

Ts'ebetso le likarolo:

1. Boitsebiso: tšepe e sa hloekang 304 / 316L kapa tšepe e bonolo Q235;

2. Phekolo ea sefahleho: pente (tšepe e bonolo), polishing / sandblasting (tšepe e sa hloekang);

3. Ribone agitator: mekhahlelo e habeli & litsela tse peli;

4. Tanka ea motsoako: tanka e tšekaletseng, e bōpehileng joaloka U;

5. Shaft: e rapameng, e sekoti, ea bohlokoa e le 'ngoe;

6. Nako ea ho kopanya: metsotso ea 5-15;

7. Mohlala oa ho sebetsa: ho kopanya batch;

8. Motlatsi oa lebelo: cycloid reducer;

9. Lebelo la ho potoloha: lebelo le tsitsitseng;

10. Main shaft tiiso: (Teflon) stuffing tiiso kapa air purge tiiso;

11. Li-openings: sehokelo sa ho fepa, sekoti, le ho hlahloba / boema-kepe ba khokahano;

12. Valofo ea ho ntša metsi: valve ea pneumatic kapa manual flap discharge;

13. Boemo ba ho sebetsa: NPT (khatello e tloaelehileng le mocheso);

14. Ha se mosebetsi o boima: mixer e ke ke ea qala ka thepa ea ho kenya;

15. Matla a matla: 220V 50HZ mohato o le mong / 380V 50HZ 3 mohato;

16. Lisebelisuoa tsa elektronike tseo e seng tsa bopaki (enjene, lisebelisoa tsa elektroniki, khabinete ea taolo);

Jet Nozzle

Classified Wheel