Indasteri ea Battery le Lintho Tse Ling Tsa Lik'hemik'hale Sebelisa Fluidized-bed Jet Mill

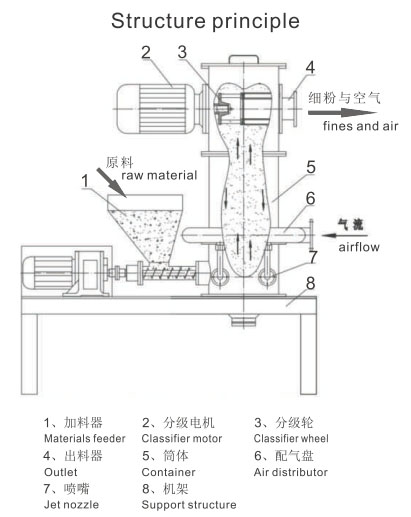

Fluidized bed pneumatic mill ke sesebelisoa se sebelisetsoang ho sila lisebelisoa tse omeletseng ho fihlela phofo e phahameng, ka sebopeho sa mantlha ka tsela e latelang:

Sehlahisoa ke mokelikeli oa bethe o nang le metsi o nang le moea oa khatello e le mokhoa oa ho senya.'Mele oa leloala o arotsoe ka likarolo tse 3, e leng sebaka sa ho senya, sebaka sa phetisetso le sebaka sa ho hlophisa.Sebaka sa Grading se fanoa ka lebili la ho hlophisa, 'me lebelo le ka fetoloa ke converter.Kamore ea ho senya e entsoe ka nozzle e senyang, feeder, joalo-joalo The ring sir supply disc ka ntle ho canister e senyang e kopantsoe le nozzle e senyang.

Thepa e kena ka phapusing e silakanyang ka thepa e fepang.Moea o hatelitsoeng o kena ka phaposing e pshatlehang ka lebelo le phahameng ka li-nozzles tse 4 tse silakanyang tse hlomelitsoeng ka ho khetheha.Thepa e fumana ho potlakisa phallo ea jetting ea ultrasonic mme e ama khafetsa le ho thulana sebakeng se bohareng sa phaposi e sithabetsang ho fihlela e pshatleha.Thepa e sithabetseng e kena ka phapusing ea maemo le phallo ea phallo.Hobane mabili a greding a bilika ka lebelo le phahameng, ha thepa e nyoloha, likaroloana li tlas'a matla a centrifugal a entsoeng ho tloha ho li-rotor tsa kereiti hammoho le matla a bohareng a entsoeng ho tloha ho viscosity ea moea.Ha likaroloana li le tlas'a matla a centrifugal a maholo ho feta matla a centripetal, likaroloana tse mahoashe tse nang le bophara bo boholo ho feta likaroloana tse hlokahalang tsa ho hlophisa li ke ke tsa kena ka kamoreng e ka hare ea lebili la ho hlophisa 'me li tla khutlela phaposing ea ho pshatla hore e pshatlehe.Likaroloana tse ntle tse tsamaellanang le bophara ba likaroloana tse hlokahalang tsa kereiti li tla kena lebiling la kereiti ebe li phalla ka har'a sekhethoa sa leholiotsoana sa kamore e ka hare ea lebili le tsamaisang moea ebe li bokelloa ke mokelli.Moea o hloekisitsoeng o lokolloa ho tsoa ho mochine oa moea ka mor'a phekolo ea mokotla oa sefe.

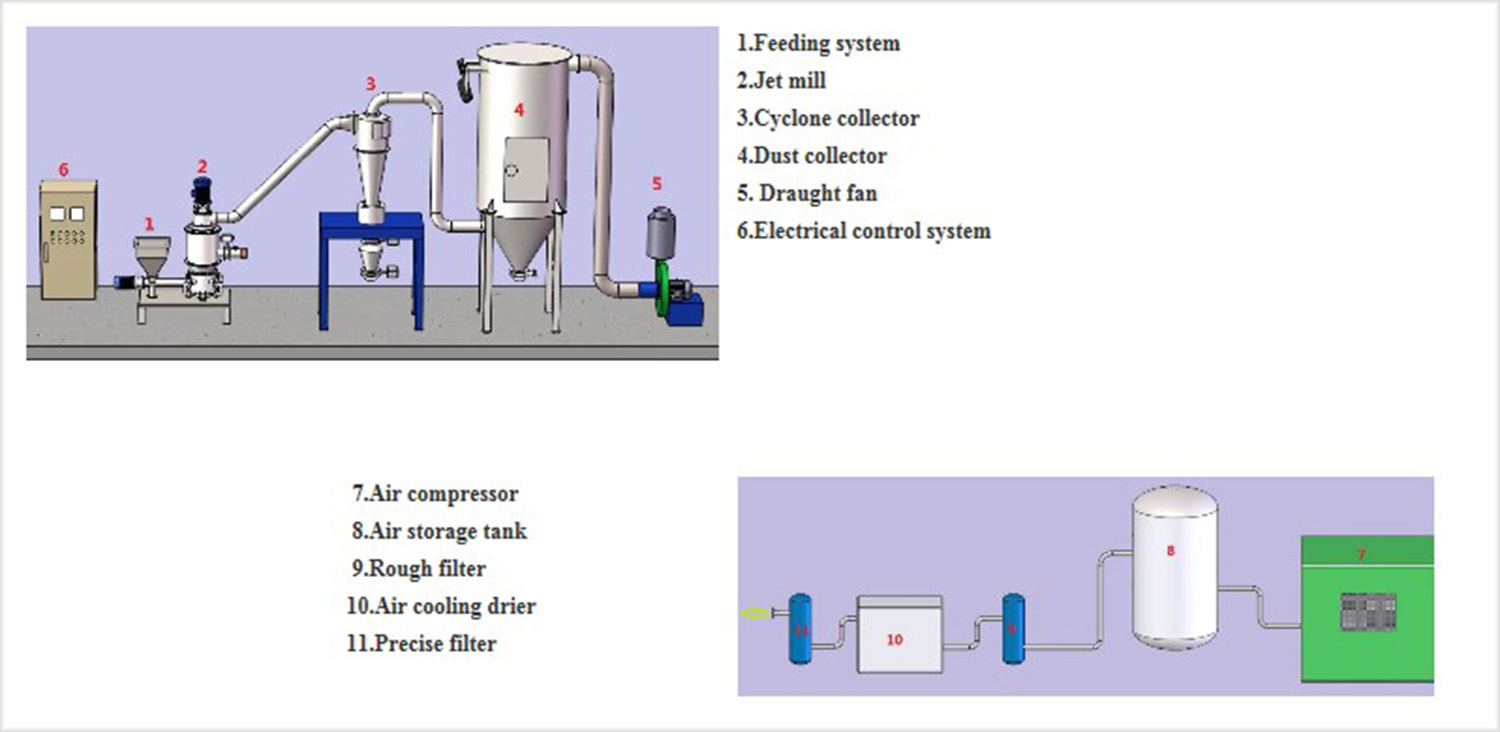

Pulverizer ea pneumatic e entsoe ka compressor ea moea, remorer ea oli, tanka ea khase, se omisang sehatsetsi, sefahla sa moea, bethe ea pneumatic pulverizer e nang le metsi, karohano ea leholiotsoana, mokelli, mochini o kenyang moea le tse ling.

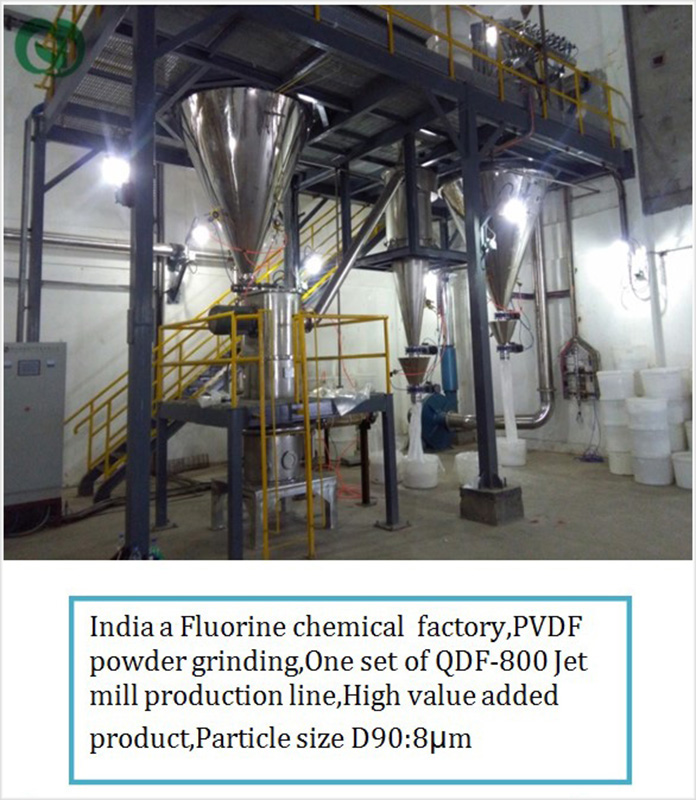

Detail show

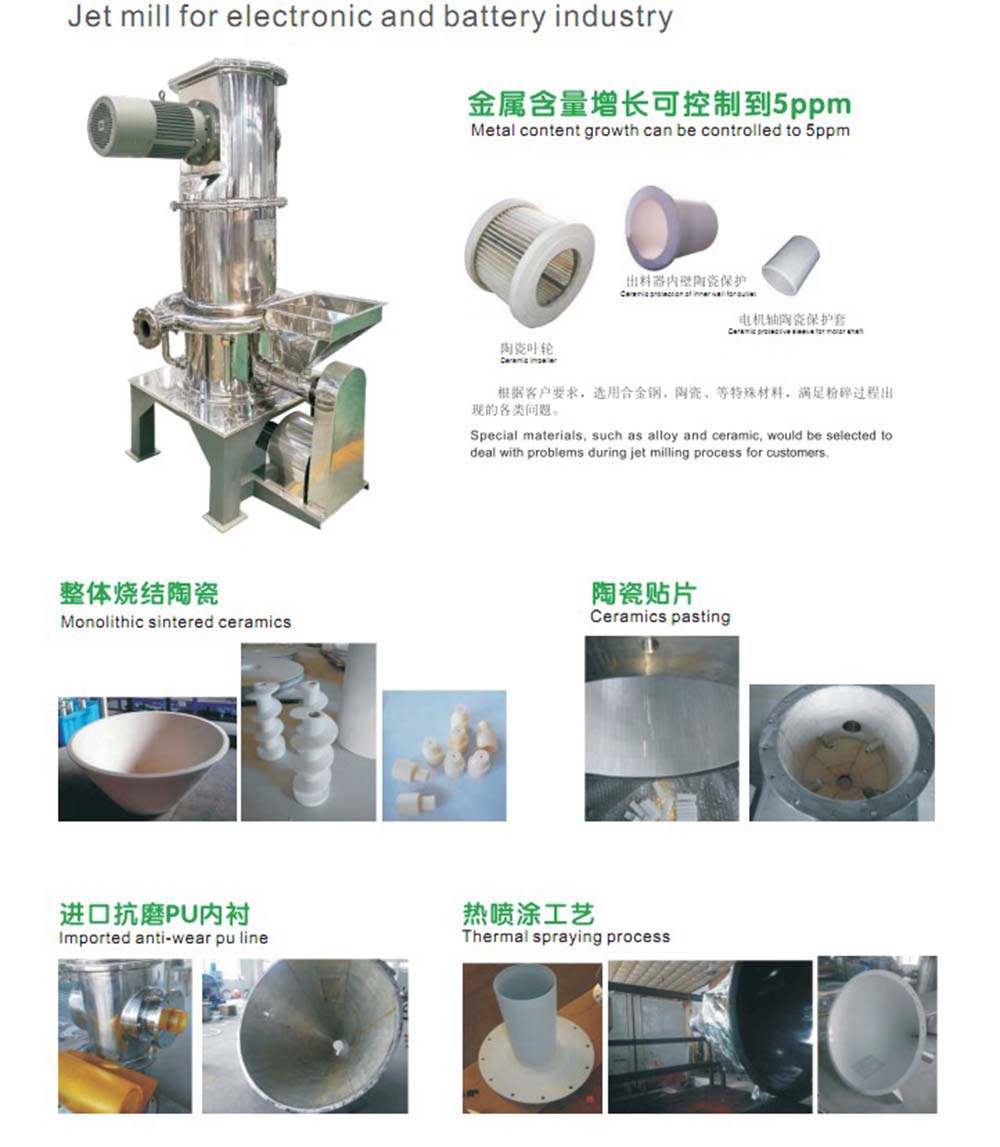

Li-ceramics tsa ho peista le PU lining likarolong tse feletseng tsa ho sila tse kopanang le lihlahisoa ho qoba tšepe e senyehileng e ka lebisang liphellong tse fosahetseng tsa lihlahisoa tsa ho qetela.

1.Liaparo tsa ceramic tse nepahetseng, 100% e felisa tšilafalo ea tšepe ho tloha ts'ebetsong ea lihlopha tsa thepa ho netefatsa bohloeki ba lihlahisoa.Haholo-holo a loketse bakeng sa litlhoko tsa dikahare tsa tšepe tsa thepa ea elektronike, tse kang cobalt high acid, lithium manganese acid, lithium iron phosphate, Ternary Material, lithium carbonate le Acid lithium nickel le cobalt joalo-joalo lisebelisoa tsa cathode tsa betri.

2. Ha ho na ho phahama ha mocheso: Mocheso o ke ke oa eketseha ha lisebelisoa li phunyeletsoa tlas'a maemo a ho sebetsa a ho atolosa pneumatic 'me mocheso o ka har'a leloala o bolokiloe o tloaelehile.

3.Endurance: E sebelisoa ho thepa e nang le Mohs Hardness ka tlase ho Kereiti ea 9. kaha phello ea ho sila e ama feela ts'ebetso le ho thulana har'a lithollo ho e-na le ho thula lebota .

4.Energy-e sebetsang hantle: Ho boloka 30% -40% ha ho bapisoa le li-pulverizer tse ling tsa moea.

Khase ea 5.Inert e ka sebelisoa e le mecha ea litaba bakeng sa ho sila lintho tse tukang le tse phatlohang.

6. Tsamaiso eohle e sithabetse, lerōle le tlaase, lerata le tlaase, mokhoa oa tlhahiso o hloekile le tšireletso ea tikoloho.

7. Sistimi e amohela taolo e bohlale ea skrineng sa ho ama, ts'ebetso e bonolo le taolo e nepahetseng.

8.Sebopeho se sephara: kamore ea mochine o moholo o kopanya potoloho ea ho koala bakeng sa ho senya.

Chate ea phallo ke ts'ebetso e tloaelehileng ea ho sila, 'me e ka fetoloa bakeng sa bareki.

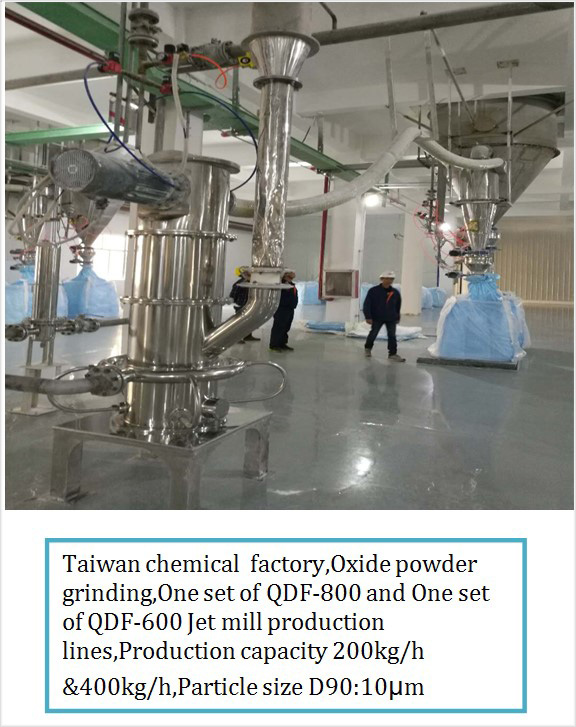

| mohlala | QDF-120 | QDF-200 | QDF-300 | QDF-400 | QDF-600 | QDF-800 |

| Khatello ea ho sebetsa (Mpa) | 0.75~0,85 | 0.75~0,85 | 0.75~0,85 | 0.75~0,85 | 0.75~0,85 | 0.75~0,85 |

| Tšebeliso ea moea (m3/mets) | 2 | 3 | 6 | 10 | 20 | 40 |

| Bophara ba lintho tse feptjoang (mesh) | 100~325 | 100~325 | 100~325 | 100~325 | 100~325 | 100~325 |

| Botle ba ho silakanya(d97μm) | 0.5-80 | 0.5-80 | 0.5-80 | 0.5-80 | 0.5-80 | 0.5-80 |

| Bokhoni (kg/h) | 0.5-15 | 10-120 | 50-260 | 80-450 | 200-600 | 400 ~ 1500 |

| Matla a kentsoeng (kw) | 20 | 40 | 57 | 88 | 176 | 349 |

| Lintho tse bonahalang | Mofuta | Bophara ba likaroloana tse feptjoang | Bophara ba likaroloana tse lahliloeng | Sephetho(kg/h) | Tšebeliso ea moea (m3/mets) |

| Cerium oxide | QDF300 | 400(Mesh) | d974.69μm | 30 | 6 |

| E thibelang lelakabe | QDF300 | 400(Mesh) | d978.04μm | 10 | 6 |

| Chromium | QDF300 | 150(Mesh) | d974.50μm | 25 | 6 |

| Phekolo ea phrophyllite | QDF300 | 150(Mesh) | d977.30μm | 80 | 6 |

| Mokokotlo | QDF300 | 300(Mesh) | d974.78μm | 25 | 6 |

| Talcum | QDF400 | 325(Mesh) | d97,10μm | 180 | 10 |

| Talcum | QDF600 | 325(Mesh) | d97,10μm | 500 | 20 |

| Talcum | QDF800 | 325(Mesh) | d97,10μm | 1200 | 40 |

| Talcum | QDF800 | 325(Mesh) | d974.8μm | 260 | 40 |

| Khalsiamo | QDF400 | 325(Mesh) | d502,50μm | 116 | 10 |

| Khalsiamo | QDF600 | 325(Mesh) | d502,50μm | 260 | 20 |

| Magnesium | QDF400 | 325(Mesh) | d50,2.04μm | 160 | 10 |

| Alumina | QDF400 | 150(Mesh) | d972.07μm | 30 | 10 |

| Matla a perela | QDF400 | 300(Mesh) | d976.10μm | 145 | 10 |

| Quartz | QDF400 | 200(Mesh) | d50,3.19μm | 60 | 10 |

| Barite | QDF400 | 325(Mesh) | d501,45μm | 180 | 10 |

| Motho ya phophomang | QDF400 | d5011.52μm | d501,70μm | 61 | 10 |

| Kaolin ea mobu | QDF600 | 400(Mesh) | d50,2.02μm | 135 | 20 |

| Lithium | QDF400 | 200(Mesh) | d501,30μm | 60 | 10 |

| Kirara | QDF600 | 400(Mesh) | d503.34μm | 180 | 20 |

| PBDE | QDF400 | 325(Mesh) | d973.50μm | 150 | 10 |

| AGR | QDF400 | 500(Mesh) | d973.65μm | 250 | 10 |

| Graphite | QDF600 | d50,3.87μm | d50,1.19μm | 700 | 20 |

| Graphite | QDF600 | d50,3.87μm | d50,1.00μm | 390 | 20 |

| Graphite | QDF600 | d50,3.87μm | d500.79μm | 290 | 20 |

| Graphite | QDF600 | d50,3.87μm | d500.66μm | 90 | 20 |

| Concave-convex | QDF800 | 300(Mesh) | d97,10μm | 1000 | 40 |

| Silicone e ntšo | QDF800 | 60(Mesh) | 400(Mesh) | 1000 | 40 |